一、进口压力自紧式锻钢闸阀产品介绍:

进口压力自紧式锻钢闸阀,Pressure self tightening type forged steel gate valve,是指采用压力自紧式阀盖,按这种设计形式设计的阀门,其阀体与阀盖螺纹连接,内压自密封环密封的闸阀。

美国威盾VTON锻钢高压闸阀适用于Class150~2500 、工作温度 -29~425℃(碳钢)或 -29~500℃(不锈钢)的小口径管路上,用于截断或接通管路中的介质,选用不同的材质,可分别适用于水、蒸汽、油品、硝酸、醋酸、氧化性介质、尿素等多种介质。

Pressure self tightening type forged steel gate valve refers to a gate valve designed with a pressure self tightening valve cover. The valve body is threaded to the valve cover and sealed with an internal pressure self sealing ring.

VTON forged steel high-pressure gate valve is suitable for small diameter pipelines with a working temperature of -29-425 ℃ (carbon steel) or -29-500 ℃ (stainless steel) in Class 150-2500. It is used to cut off or connect the medium in the pipeline. Different materials are selected and can be used for various media such as water, steam, oil, nitric acid, acetic acid, oxidizing media, urea, etc.

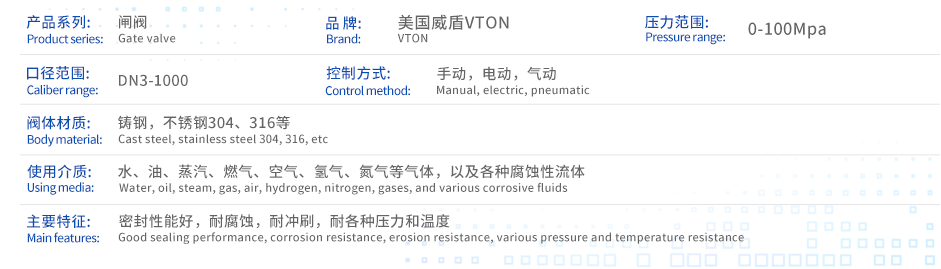

二、进口压力自紧式锻钢闸阀参数

口径:DN15-50

适用温度:-200~650℃

压力:PN10-32Mpa,ANSI 150~2500LB

连接方式:法兰,螺纹,承插焊,对焊

阀体材质:A105、LF2、F316

阀板材质:A105、F316

阀杆材质:F6,F316

阀座材质:Satellite

三、进口压力自紧式锻钢闸阀特点

1.锻钢阀门采用压力自紧式密封,阀体支管两端为焊接连接。

2.阀坐、阀瓣密封面采用钴基硬质合金等离子喷焊而成,耐磨、抗擦伤性能好。

3.阀杆经抗腐蚀性氮化处理,有良好的抗腐蚀性和抗擦伤性。

4、全径锻钢高压闸阀或缩径锻钢高压闸阀

5、明杆支架式(OS&Y)

6、自定心压板压套式

7、螺纹连接内压自紧式阀盖

8、整体式上密封座

9、承插端符合ASME B16.11

10、螺纹连接端(NPT)符合ANSI/ASME B1.20.1

1. The forged steel valve adopts a pressure self tightening seal, and the two ends of the valve body branch pipe are welded connections.

2. The sealing surfaces of the valve seat and valve disc are made of cobalt based hard alloy plasma spray welding, which has good wear resistance and scratch resistance.

3. The valve stem has undergone anti-corrosion nitriding treatment, which has good corrosion resistance and scratch resistance.

4. Full diameter forged steel high-pressure gate valve or reduced diameter forged steel high-pressure gate valve

5. OS&Y

6. Self centering pressure plate sleeve type

7. Screw connection internal pressure self tightening valve cover

8. Integrated upper sealing seat

9. Socket end in accordance with ASME B16.11

10. Thread connection end (NPT) complies with ANSI/ASME B1.20.1

关注我们

微信联系

Copyright © 2013-2023 All Rights Reserved. 粤ICP备17016233号

ENGLISH

ENGLISH