一、进口锻钢自密封截止阀概述

进口锻钢自密封截止阀(威盾VTON),Forged steel self-sealing globe valve,也叫压力自密封截止阀,压力自紧式截止阀,是指采用压力自紧式阀盖,按这种设计形式设计的阀门,其阀体与阀盖用螺纹连接,内压自密环密封的截止阀。压力也高,密封越紧,密封性能极佳,使用于高压的密封要求较高的小口径管道场合。

美国威盾VTON锻钢自密封截止阀适用于钢铁厂、石油、化工、煤气、锅炉、造纸、纺织、医药、食品、船舶、供排水、能源、多晶硅、电力等行业工业管道,用于截断或接通管路中的介质,选用不同的材质,可分别适用于水、蒸汽、油品、硝酸、醋酸、氧化性介质、尿素等多种介质。锻钢截止阀流体阻力小,适用的压力、温度范围大,介质流动方向不受限制,密封性能良好。

Forged steel self sealing globe valve (VTON), also known as pressure self sealing globe valve or pressure self tightening globe valve, refers to a valve designed with a pressure self tightening valve cover and a threaded connection between the valve body and cover, and an internal pressure self sealing ring seal. The pressure is also high, the sealing is tighter, and the sealing performance is excellent. It is used in small diameter pipelines with high pressure sealing requirements.

The American Weidun VTON forged steel self sealing globe valve is suitable for industrial pipelines in industries such as steel mills, petroleum, chemical, gas, boilers, papermaking, textiles, pharmaceuticals, food, ships, water supply and drainage, energy, polycrystalline silicon, and power. It is used to cut off or connect the medium in the pipeline. Different materials are selected and can be used for various media such as water, steam, oil, nitric acid, acetic acid, oxidizing medium, and urea. Forged steel globe valves have low fluid resistance, a wide range of applicable pressure and temperature, unrestricted medium flow direction, and good sealing performance.

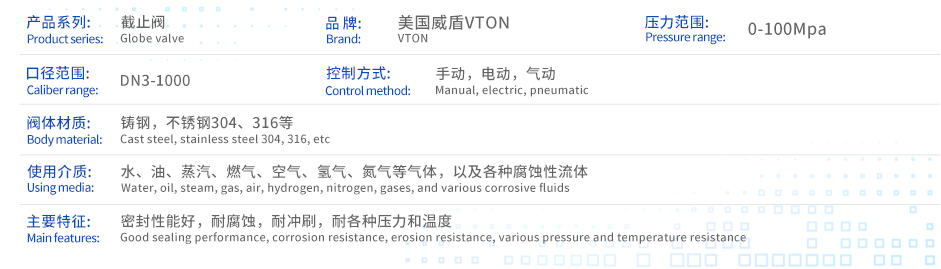

二、进口锻钢自密封截止阀参数

公称压力:PN1.0-32.0MPa、ANSI CLASS 150-2500、JIS10-20K

公称通径:DN10~500、NPS 1/2 ~36"

连接方式:对焊、承插焊

适用温度:-196℃~700℃

驱动方式:手动、伞齿轮传动、气动、电动、液动、气液联动、电液联动

三、进口锻钢自密封截止阀特点

1、结构紧凑、性能可靠、外观精美。

2、采用A105阀体,密封环为聚四氟乙烯工程

3、塑料,耐高压、密封性好,手把搬动灵活舒适。

4、阀芯、阀座密封面经过淬火,在高温、高压下不易磨损、擦伤,密封性好,寿命长。

5、阀盖设计有二个90°密封锥面,锥面一与密封圈组合行成双重密封防止流体外漏;

6、阀门全开时,锥面二与阀杆上锥面楔合,阻止介质流向填料。

1. Compact structure, reliable performance, and exquisite appearance.

2. Adopting A105 valve body and sealing ring made of polytetrafluoroethylene engineering

3. Plastic, resistant to high pressure, good sealing, and flexible and comfortable handling.

4. The sealing surface of the valve core and valve seat is quenched, which is not easy to wear or scratch under high temperature and pressure, has good sealing performance, and a long service life.

5. The valve cover is designed with two 90 ° sealing conical surfaces, and the conical surface is combined with the sealing ring to form a double seal to prevent fluid leakage;

6. When the valve is fully open, cone surface two wedges with the cone surface on the valve stem to prevent the medium from flowing towards the packing.

关注我们

微信联系

Copyright © 2013-2023 All Rights Reserved. 粤ICP备17016233号

ENGLISH

ENGLISH