一、进口天然气高压球阀概述

进口天然气高压球阀(美国威盾VTON),Natural gas high-pressure ball valve,也叫加气站高压球阀,CNG高压球阀,法兰高压球阀,焊接高压球阀)是指采用碳钢或者不锈钢304或者316L为阀体材质,压力可以达到32Mpa或者50Mpa,用于各类CNG加气站高压管路,液压高压管路下的启闭装置。

Natural gas high-pressure ball valve (VTON, also known as gas station high-pressure ball valve, CNG high-pressure ball valve, flange high-pressure ball valve, welded high-pressure ball valve) refers to a valve body material made of carbon steel or stainless steel 304 or 316L, with a pressure of up to 32Mpa or 50Mpa. It is used as an opening and closing device in various CNG gas station high-pressure pipelines and hydraulic high-pressure pipelines.

一、进口天然气高压球阀特点

1、 天然气高压球阀优异的承受高压性能和独特的组合密封,使安全系数更高;

2、 结构特殊优化,适用于高压差、高频率、宽温幅、长时间使用环境,获得高压天然气用户的一致好评。

3、 天然气专用球阀主要受力部件应用威盾材料,阀杆受力区域都用该种材料制成的上下轴套进行包裹。

4、 上轴套将原来金属与金属之间的摩擦变成了金属与非金属之间的摩擦,即使在高循环工作条件下也能保证阀门不会外漏。下轴套采用凸肩式设计加大了受力面积,不仅增强了密封效果,更能有效缓冲高压差时阀杆承担的巨大冲击力

5、 球体口径增大60%,有效分散压力冲击,并使球体与阀座密封接触面积增大,如DN15 球阀,球体作用在阀座的受力面积为4.52cm2,能承受2.26 吨压力,较普通高压阀提升70%

6、 V型阀座设计, 高压下提供背压,减少球体偏转角度;低压下增加密封预紧力,保证阀门工作时的稳定性

7、 主体采用高压冲击锻打,阀门耐压最高达500Bar

8、 防火和防静电设计,防火设计及试验遵循API6FA和API607标准

1. The excellent high-pressure performance and unique combination sealing of natural gas high-pressure ball valves result in a higher safety factor;

2. Specially optimized in structure, suitable for high pressure differential, high frequency, wide temperature range, and long-term use environments, receiving unanimous praise from high-pressure natural gas users.

3. The main load-bearing components of natural gas special ball valves are made of Weidun material, and the force bearing area of the valve stem is wrapped with upper and lower shaft sleeves made of this material.

4. The upper shaft sleeve transforms the friction between metal and metal into friction between metal and non-metal, ensuring that the valve will not leak even under high cycle working conditions. The lower shaft sleeve adopts a raised shoulder design to increase the stress area, not only enhancing the sealing effect, but also effectively buffering the huge impact force borne by the valve stem during high pressure difference

5. The diameter of the sphere increases by 60%, effectively dispersing pressure impact and increasing the contact area between the sphere and the valve seat. For example, for DN15 ball valves, the force area of the sphere acting on the valve seat is 4.52cm2, which can withstand a pressure of 2.26 tons, which is 70% higher than ordinary high-pressure valves

6. V-shaped valve seat design provides back pressure under high pressure, reducing the deflection angle of the ball; Increase the sealing pre tightening force under low pressure to ensure the stability of the valve during operation

7. The main body adopts high-pressure impact forging, and the valve can withstand pressure up to 500Bar

8. Fire and anti-static design, fire protection design and testing follow API6FA and API607 standards

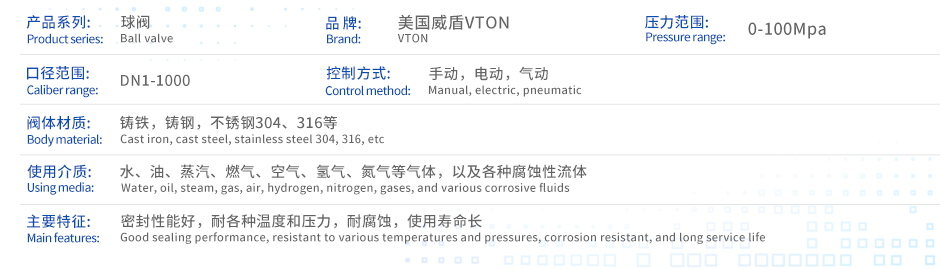

三、进口天然气高压球阀技术参数

尺 寸: DN6 – DN80

连 接: G 螺纹ISO0228、ISO 7/1RP 标准、NPT 螺纹、焊接、法兰

压 力: PN500 /PSI7000(DN6-DN20)

PN420 /PSI6000(DN6-DN50)

PN320/PSI4500(DN6-DN65)

PN160/PSI2400(DN6-DN80)

阀座密封: 特殊的聚酰胺(尼龙)材料,MTU

介 质: 天然气、油、石化和石油产品

材 质: 碳钢、不锈钢

控制方式:手动、气动、电动

工作温度: -40℃至+200℃

关注我们

微信联系

Copyright © 2013-2023 All Rights Reserved. 粤ICP备17016233号

ENGLISH

ENGLISH