一、进口碳钢焊接球阀概述

进口碳钢焊接球阀美国威盾VTON,Carbon steel welded ball valve,也叫铸钢全焊接球阀,20号钢全焊接球阀,是指采用20号钢为阀体,以不锈钢为球体,采用全焊接的连接方式,采用碳强化PTFE斜面弹性密封圈负压在球面上,使密封达到零泄漏,使用寿命长。应用于天然气、石油、供热、化工及热电管网等长输管线领域。

Carbon steel welded ball valve, also known as cast steel fully welded ball valve or 20 steel fully welded ball valve, refers to the use of 20 steel as the valve body, stainless steel as the ball, and a fully welded connection method. It uses carbon reinforced PTFE inclined elastic sealing ring negative pressure on the spherical surface to achieve zero leakage and long service life. Applied in long-distance pipeline fields such as natural gas, oil, heating, chemical and thermal power pipelines.

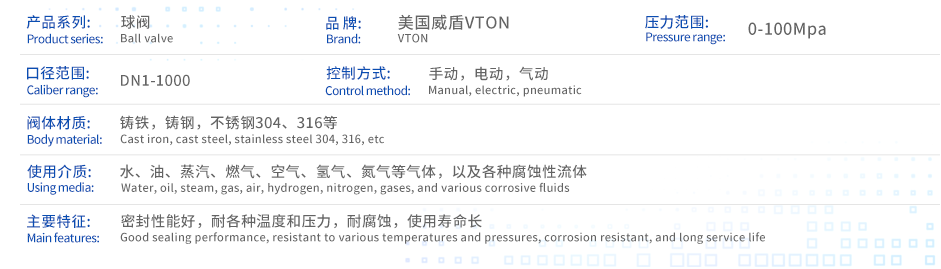

二、进口碳钢全焊接球阀参数

1):阀体:碳钢ST37.0,A106-B;20号钢

2):球体:不锈钢304或316

3):阀杆:2Cr13

4):阀杆密封:全氟像胶

5):球体密封:RTFE(PTFE+C)

6):通径:DN15 ~1000

7):压力:PN 16 ~ 40

8):工作温度:-29℃ ~ +200℃

9):输气管道焊接球阀适应介质:石油/汽油,液化天然气/液化石油气体, 石油化工,钢铁厂,供热管道等

10):输气管道焊接球阀操作方式:手柄,齿轮(垂直/水平),电动, 涡轮

三、进口碳钢全焊接球阀特点

1):不需要维护,调整及润滑,易于安装,在低运行费用下长期可靠运行。表面采用喷塑处理技术,光泽美观,在国内已处于领先水平。不会有外部泄漏等现象。阀体是焊接结构,所以阀门重量轻且易于进行绝缘。安装调节机构,非常简便,操作手柄可以拆下,换向安装。

2):由于阀座是由碳纤维增强特氟隆密封环及碟形簧构成的,所以对压力和温度的变化适应能力强,在标注压力和温度范围内不会产生任何泄滑。

3):球体的加工过程有先进的计算机检测仪跟踪检测,所以球体的加工精度高。

4):由于阀体材料跟管道材质一样,不会出现应力不均,也不会由于地震及车辆经过地面时而产生变形,管道耐老化。

5):整体式全焊接,等径及变径通道,采用固定球及浮动球,双活塞效应密封系统,自动

注入密封剂式轴承。

6):为了防止静电,阀杆与球体以及阀杆与填料箱之间分别装有钢球和弹簧,可以保持阀门所有零件与阀体的导电,让电流通过区,释放静电。不仅防止火灾,而且防止腐蚀,实现临时性切断,以便及时检修。

7):阀杆防脱功能是因为阀杆受阀内压力影响,总产生脱离的力所以阀杆设计成防脱结构。

8):用低摩擦材料的止推垫圈支撑将压力推向阀杆,使阀杆仅仅起到传递扭矩的作用。

1) No maintenance, adjustment, or lubrication required, easy to install, and reliable long-term operation at low operating costs. The surface is treated with spray coating technology, which has a beautiful luster and is at the leading level in China. There will be no external leakage or other phenomena. The valve body is a welded structure, so the valve is lightweight and easy to insulate. Installing the adjustment mechanism is very simple, and the operating handle can be removed for reverse installation.

2) Due to the fact that the valve seat is composed of carbon fiber reinforced Teflon sealing rings and disc springs, it has strong adaptability to pressure and temperature changes, and will not produce any leakage within the marked pressure and temperature range.

3) The machining process of the sphere is tracked and detected by advanced computer detectors, so the machining accuracy of the sphere is high.

4) Due to the fact that the material of the valve body is the same as that of the pipeline, there will be no uneven stress, and there will be no deformation due to earthquakes or vehicles passing through the ground. The pipeline is resistant to aging.

5) : Integrated full welding, equal and variable diameter channels, using fixed and floating balls, dual piston effect sealing system, automatic

Inject sealing agent into the bearing.

6) To prevent static electricity, steel balls and springs are installed between the valve stem and the ball, as well as between the valve stem and the packing box, respectively, to maintain conductivity between all parts of the valve and the valve body, allowing current to pass through the area and release static electricity. Not only does it prevent fire, but it also prevents corrosion and achieves temporary cutting for timely maintenance.

7) The anti detachment function of the valve stem is designed as an anti detachment structure because the valve stem is affected by the pressure inside the valve, resulting in a total force of detachment.

8) Use a low friction material thrust washer to support and push pressure towards the valve stem, so that the valve stem only serves to transmit torque.

关注我们

微信联系

Copyright © 2013-2023 All Rights Reserved. 粤ICP备17016233号

ENGLISH

ENGLISH