一、进口一体式焊接球阀概述

进口一体式全焊接球阀(美国威盾VTON),也叫一体式全焊接球阀,整体式焊接球阀,一体结构焊接球阀,一体锻造焊接球阀,是指采用碳钢无缝钢管压制成型整体式,以不锈钢为球体,采用全焊接的连接方式,采用碳强化PTFE斜面弹性密封圈负压在球面上,用于热水、蒸汽等管道介质,使密封达到零泄漏的球阀。广泛应用于城市燃气、城市供热、石油化工、造船、钢铁、调压站、发电厂等各类管道设备上。

进口一体式焊接球阀用途:

城市煤气:煤气输出管道、主干线及各支线供应管道等。

集中供热:大型供热设备输出管线、主干线、支线。

热交换机:管道及各回路启闭。

钢铁厂:各种流体管道、废气择放管道、煤气和热力供应管道、燃料供应管道。

各种工业设备:各种热处理管道、各种工业煤气和热力管道。

Integrated all welded ball valve (VTON), also known as integrated all welded ball valve, integrated welded ball valve, integrated structure welded ball valve, and integrated forged welded ball valve, refers to a ball valve that is pressed and formed using carbon steel seamless steel pipe, made of stainless steel as the ball, using a fully welded connection method, and using carbon reinforced PTFE inclined elastic sealing ring negative pressure on the spherical surface. It is used for hot water, steam and other pipeline media to achieve zero leakage sealing. Widely used in various pipeline equipment such as urban gas, urban heating, petrochemicals, shipbuilding, steel, pressure regulating stations, power plants, etc.

Imported integrated welded ball valve Purpose:

Urban gas: gas output pipelines, main and branch supply pipelines, etc.

Centralized heating: Large scale heating equipment output pipelines, main pipelines, and branch pipelines.

Heat exchanger: opening and closing of pipelines and various circuits.

Steel plant: various fluid pipelines, waste gas selective discharge pipelines, gas and heat supply pipelines, fuel supply pipelines.

Various industrial equipment: various heat treatment pipelines, various industrial gas and heating pipelines.

二、进口一体式焊接球阀特点

1、一体式全焊接球阀,不会有外部泄漏等现象,由于阀座是由碳化特氟隆密封环及咖弹簧构成的,以对压力和温度的变化适应能力强,标注压力和温度范围内不会产生任何泄滑。

2、球体的加工过程有先进的计算机检测仪跟踪检测,以球体的加工精度高。

3、由于阀体材料跟管道材质一样,会出现应力不均,不会由于地震及车辆经过地面时而产生变形,管道耐老化。

4、密封环本体采用含量20%C(碳素)的PTFE材质,保障完全无泄漏(0%)。

1. The integrated fully welded ball valve will not have external leakage or other phenomena. As the valve seat is composed of carbonized PTFE sealing rings and coffee springs, it has strong adaptability to pressure and temperature changes, and there will be no leakage within the marked pressure and temperature range.

2. The machining process of the sphere is tracked and detected by advanced computer detectors, resulting in high machining accuracy of the sphere.

3. Due to the fact that the valve body material is the same as the pipeline material, there will be uneven stress and deformation will not occur due to earthquakes or vehicles passing through the ground. The pipeline is resistant to aging.

4. The sealing ring body is made of PTFE material with a content of 20% C (carbon), ensuring complete leakage free (0%).

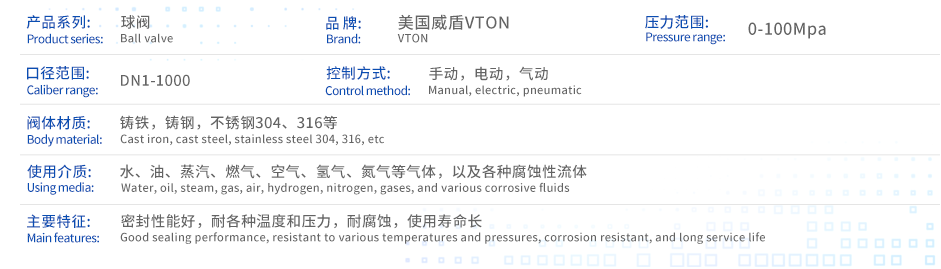

三、进口一体式焊接球阀参数

连接方式:焊接,对焊

压力等级:150~600LB,1.6MPa~ 4.0MPa

产品规格:1/2 ~ 40 , DN15 ~ 1200mm

产品材质:WCB,A105,F11,F22,F304,F316,CF8,CF8M,WCC或根据客户要求选。

适用温度:-29℃≤t≤150 ℃(跟阀体材质及密封面材质不同所承温有差异)

适用介质:水、石油、天然气及酸碱介质等

驱动方式:电动、手动、蜗轮驱动、齿轮驱动

四、进口一体式焊接球阀安装说明

1、球阀可安装在任何位置,阀门的任何一端均可作为上游端。

2、在安装阀门时阀球应保持在全开位,否则将导致阀门的损坏。

3、如果在阀门安装时,阀球必须保持在关位,请将暴露在外的阀球表面涂上油脂。这样可保护阀球不被飞溅的焊渣损坏。

4、请勿长时间将阀门放置在半开位状态。

5、对无接管的对焊联端阀门,请切勿在阀球关位安装阀门

6、焊接说明:在预热、焊接或热应力释放时,距焊缝3”以外阀体上的任何点处温度均不能超过400 F(200℃〕。请用测温色笔检验温度。在把球阀最终焊接在管线之前,应用1”宽的保护带盖上阀门密封自三点钟至九点钟区域(阀球与阀座之间的密封和阀座与端部之间的密封〕。这样有助于防止任何杂质落入这个区域,在开工或试压之前,管线系统应清除杂质。

1. Ball valves can be installed in any position, and any end of the valve can serve as the upstream end.

2. When installing the valve, the valve ball should be kept in the fully open position, otherwise it will cause damage to the valve.

3. If the valve ball must be kept in the closed position during valve installation, please apply grease to the exposed surface of the valve ball. This can protect the valve ball from being damaged by splashing welding slag.

4. Do not leave the valve in the half open position for a long time.

5. For butt welded end valves without connecting pipes, please do not install valves in the valve ball position

6. Welding instructions: During preheating, welding, or thermal stress release, the temperature at any point on the valve body 3 "away from the weld should not exceed 400 F (200 ℃). Please use a temperature measuring color pen to check the temperature. Before finally welding the ball valve in the pipeline, cover the valve with a 1" wide protective tape from the 3 o'clock to 9 o'clock area (sealing between the valve ball and the valve seat and the sealing between the valve seat and the end). This helps to prevent any impurities from falling into this area. Before starting work or pressure testing, the pipeline system should remove impurities.

关注我们

微信联系

Copyright © 2013-2023 All Rights Reserved. 粤ICP备17016233号

ENGLISH

ENGLISH