一、进口固定球阀概述

进口固定球阀(美国威盾VTON),Fixed ball valve,也叫固定式球阀,固定球球阀,是指球体是固定的,受压后不产生移动的球阀。固定球球阀都带有浮动阀座,受介质压力后,阀座产生移动,使密封圈紧压在球体上,以保证密封。在球体的上、下轴上装有轴承,操作扭距小,适用于高压和大口径,适用于化工、石油、天然气、冶金、等行业及含硫化氢介质、杂质多、腐蚀严重的天然气长输管。

Fixed ball valve (VTON), also known as fixed ball valve, refers to a ball valve in which the ball is fixed and does not move under pressure. Fixed ball valves are equipped with floating valve seats. When subjected to medium pressure, the valve seat moves, causing the sealing ring to tightly press against the ball to ensure sealing. Bearings are installed on the upper and lower shafts of the sphere, with small operating torque, suitable for high pressure and large diameter industries, such as chemical, petroleum, natural gas, metallurgy, and natural gas long-distance pipelines containing hydrogen sulfide media, impurities, and severe corrosion.

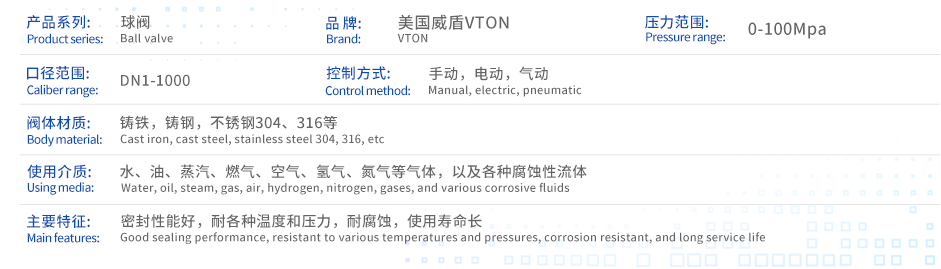

二、进口固定球阀参数特征

1、进口固定球阀适用于Class150~Class1500、PN16~PN100、JIS 10K~JIS 20K的各种管路上,适用温度:-196~350℃,用于截断或接通管路中的介质,选用不同的材质,可分别适用于输送水、蒸汽、油品、硝酸、醋酸、氧化性介质、尿素等。

2、它与浮动球阀相比,工作时,阀前流体压力在球体上产生的作用力全部传递给轴承,不会使球体向阀座移动,因而阀座不会承受过大的压力,所以 固定球阀 的转矩小、阀座变形小,密封性能稳定、使用寿命长,适用于高压、大口径场合

3、为了减少球阀的操作扭矩和增加密封的可靠程度,威盾研究了油封球阀,既在密封面间压注特制的润滑油,以形成一层油膜,即增强了密封性,又减少了操作扭矩,更适用高压大口径的球阀。

4、阀座采用弹簧结构,将阀座推向球体,保证了良好的低压密封性能

5、固定球阀阀前,阀后阀座都能密封,即所谓双向密封特性,利用自带的排放阀,阀体中腔可向外排放

6、枢轴采用防吹出保护结构,低摩擦系数的轴承等。具有性能优异,可靠性高,用途广泛

1. Fixed ball valves are suitable for various pipelines from Class150 to Class1500, PN16 to PN100, JIS 10K to JIS 20K, with a suitable temperature of -196 to 350 ℃. They are used to cut off or connect media in pipelines, and different materials are selected. They can be used to transport water, steam, oil, nitric acid, acetic acid, oxidizing media, urea, etc.

2. Compared with floating ball valves, during operation, all the force generated by the fluid pressure in front of the valve on the ball is transmitted to the bearing, which will not cause the ball to move towards the valve seat. Therefore, the valve seat will not bear excessive pressure. Therefore, the torque of the fixed ball valve is small, the deformation of the valve seat is small, the sealing performance is stable, and the service life is long. It is suitable for high-pressure and large-diameter situations

3. In order to reduce the operating torque of ball valves and increase the reliability of sealing, Weidun has studied oil sealed ball valves. It not only injects special lubricating oil between the sealing surfaces to form a layer of oil film, which enhances sealing performance but also reduces operating torque, making it more suitable for high-pressure large-diameter ball valves.

4. The valve seat adopts a spring structure, which pushes the valve seat towards the sphere, ensuring good low-pressure sealing performance

5. Both the front and back valve seats of the fixed ball valve can be sealed, which is known as the bidirectional sealing feature. By using the built-in discharge valve, the middle chamber of the valve body can be discharged outward

6. The pivot adopts an anti blow out protection structure and low friction coefficient bearings. Has excellent performance, high reliability, and a wide range of applications

关注我们

微信联系

Copyright © 2013-2023 All Rights Reserved. 粤ICP备17016233号

ENGLISH

ENGLISH